Sanitary napkins, Pads

& Diapers

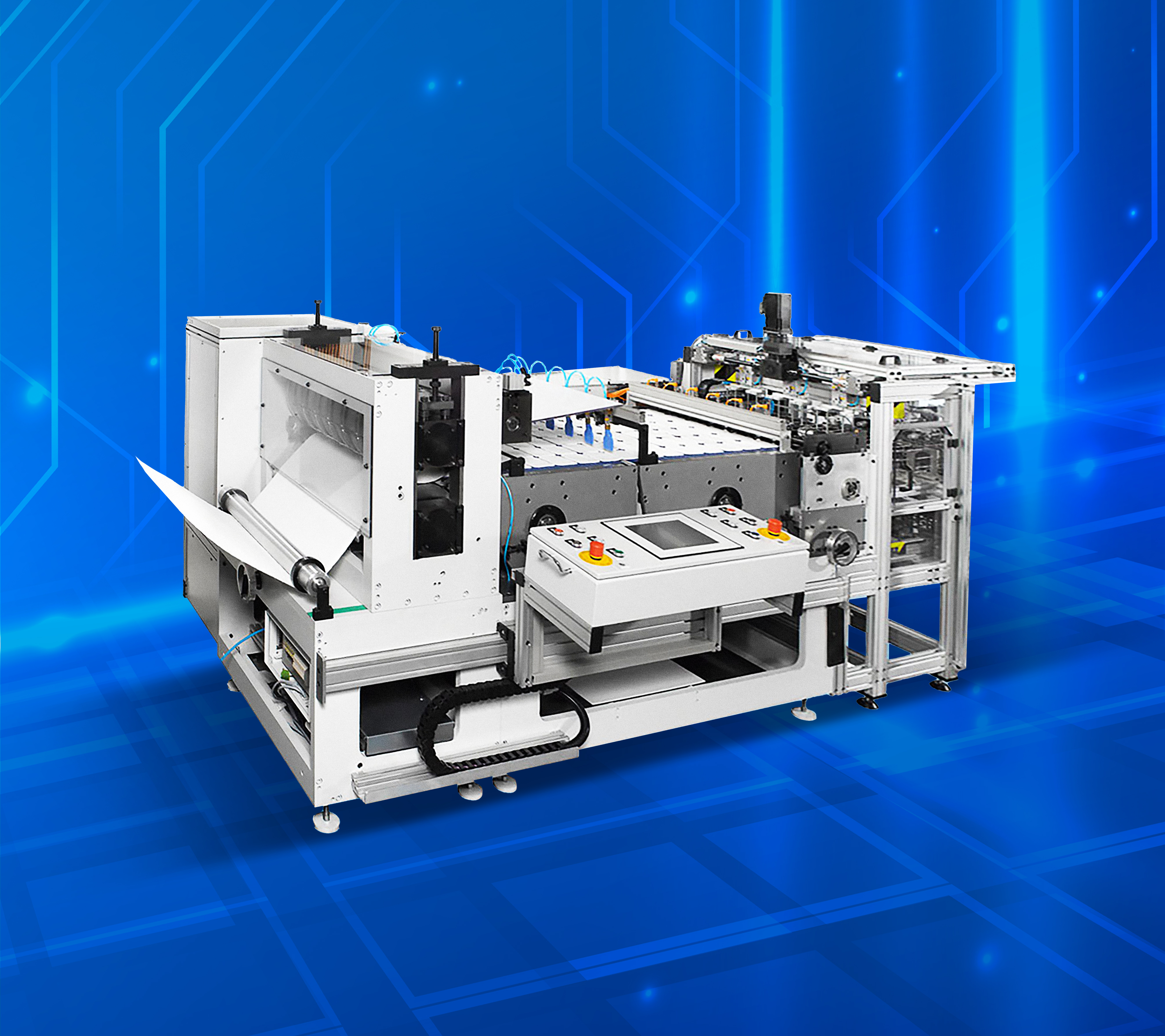

Schobertechnologies' expertise gives you a decisive productivity advantage in the processing of nonwovens and fabrics. By choosing Schobertechnologies, you will have the latest technology for processing a wide range of materials used in the manufacture of hygiene products right from the start. Whether you manufacture products for feminine hygiene, incontinence care or for operating and nursing needs: Schobertechnologies offers customised solutions for every work step, such as cutting, punching or embossing, technically perfected to achieve maximum efficiency.

Everything is possible: bandages, nappies, incontinence products, plasters, airlaid, filters

Schober offers machines with a web width of up to 700 mm for punching and stacking round, square and rectangular cotton pads. For pads with a diameter of 57 mm, up to 11 repeats across the material web are possible. The punched products are counted inline, stacked horizontally and packed automatically. Product deliveries for nested products are optionally available to minimise waste.

with interchangeable punch and die segments. Thanks to an ingenious system, free geometries can also be punched in addition to round holes - within the scope of technical possibilities - even with a narrow hole pattern.

Read all about innovative cutting, punching, creasing and embossing in our brochure "Efficient Rotary processing of films, nonwovens and textiles"