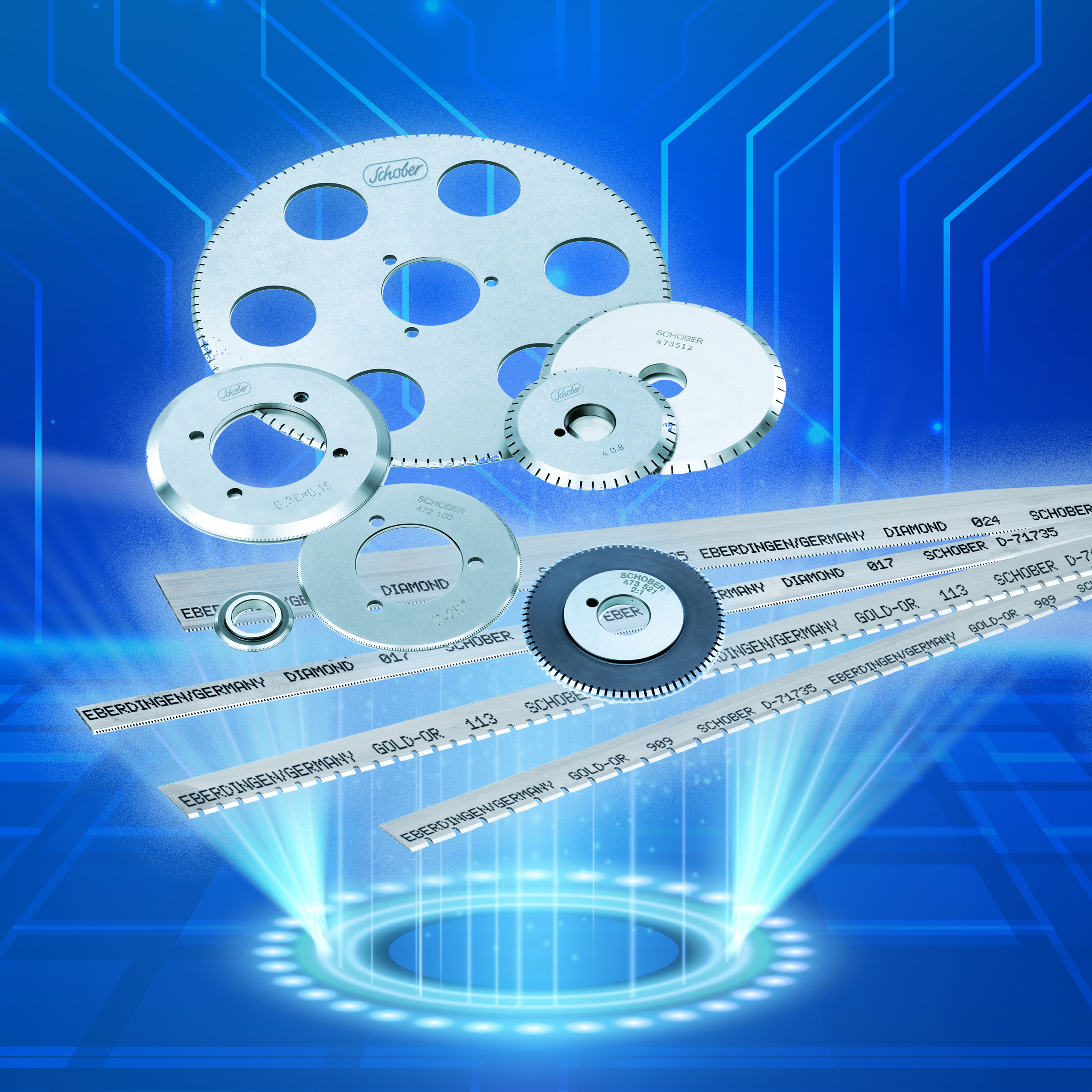

circular knives

as sharp as new!

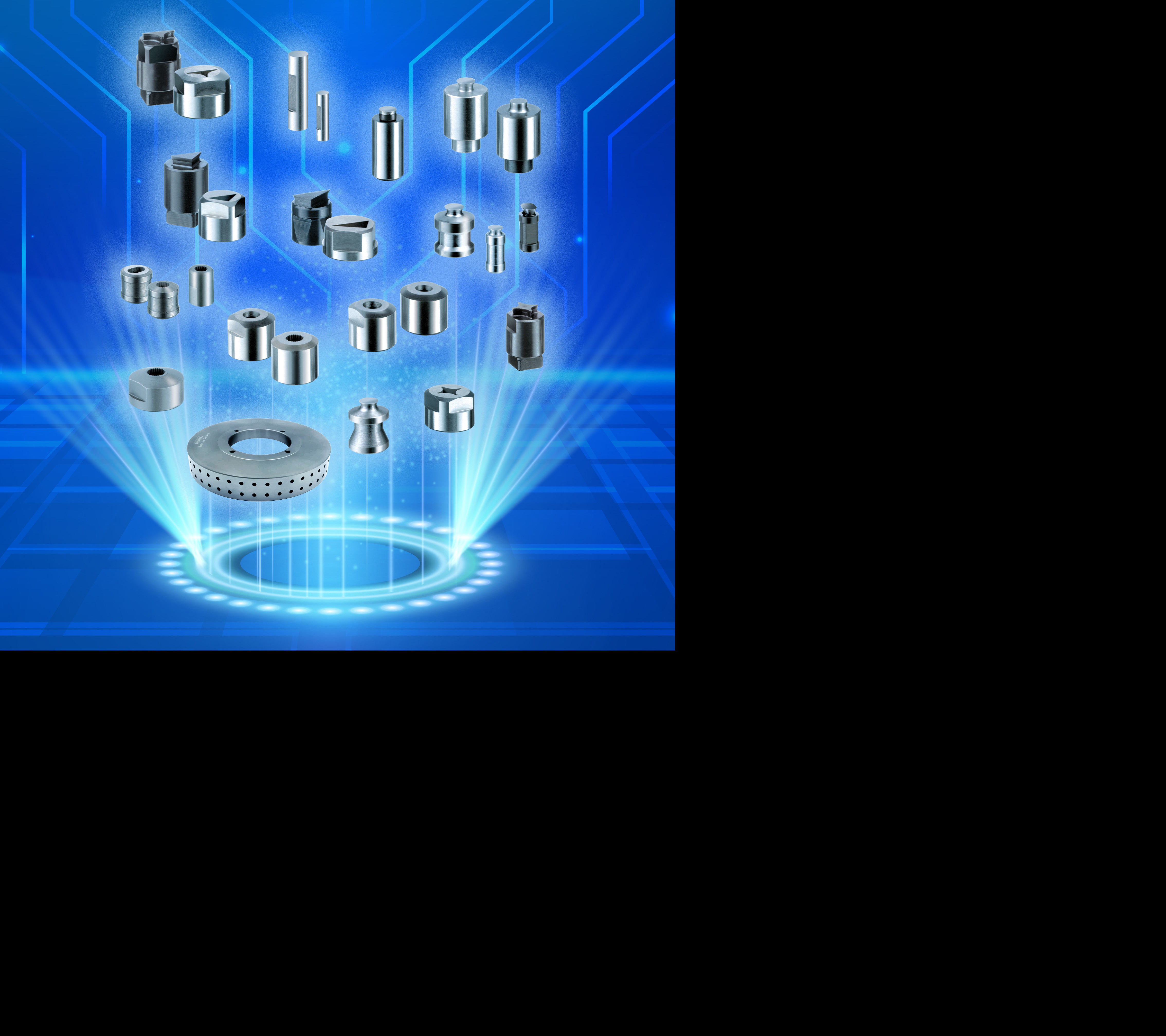

Schobertechnologies offers you a grinding and sharpening service for your own and/or third-party manufactured tools. We have extensive grinding techniques with which all cutting edge designs can be produced from carbide, longlife, HSS or superchrome.

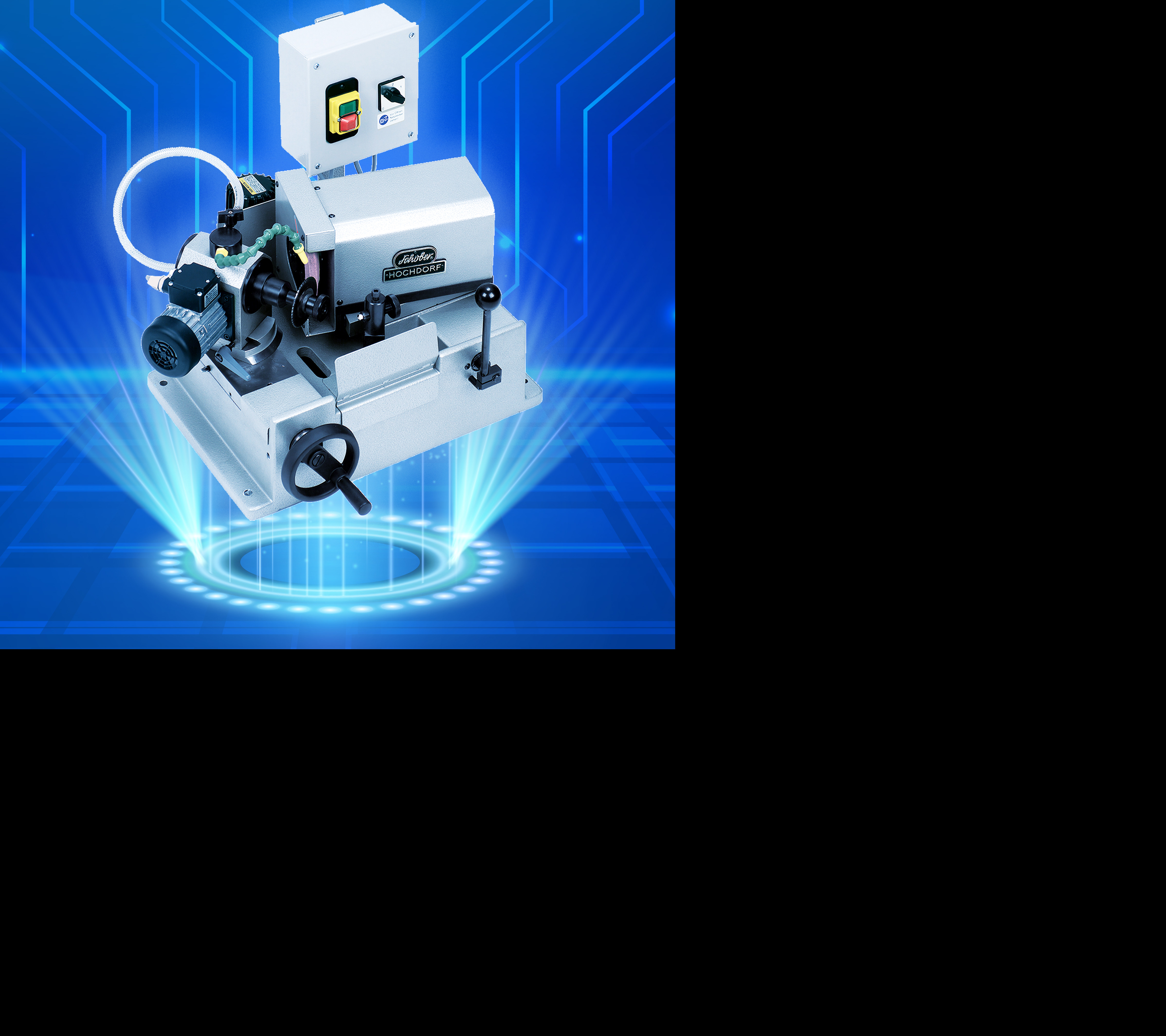

In addition, you can purchase sharpening equipment as well as test stations.

In general, this is possible, as long as the technical parameters allow economical resharpening. For an initial check, you are more than welcome to send us a photo of what needs to be re-sharpened by e-mail. Our experts will then discuss the further procedure with you.

Regrinding of circular knives can be done within one to two weeks. For form cutting cylinders, the regrinding time is between three and eight weeks, depending on the geometry and complexity.

Carbide, Longlife (powder metallurgy steel), HSS or Superchrome (tool steel)

If the materials are known and the third-party product is professionally made, it can usually be regrinded. Depending on the complexity of the tools, a program for CNC regrinding may be due. Please feel free to discuss further details with our parts department.

With our circular knife grinding machine S6, you can grind your circular knives independently with a few simple steps. Get 5% off our demonstration model now (only while stocks last).